UV Bulb and Sleeve Replacement: Protecting Your Well Water Year After Year

By Jared Beviano | Water Wizards Filtration

I got a call from a family in Loxahatchee last spring that still bothers me when I think about it.

They'd had a UV sterilization system on their well for six years. Installed by another company, working fine—or so they thought. The blue light was still glowing through the little window on the chamber. Everything looked normal.

Then their daughter got sick. Stomach cramps, vomiting, the whole deal. A few days later, their son had the same symptoms. Then mom. The pediatrician ran tests and confirmed a bacterial infection—the kind you get from contaminated water.

When I got out there to inspect their system, the problem was obvious within seconds. The UV bulb was original—six years old, never replaced. And when I pulled the quartz sleeve out, it was so coated with mineral scale that you could barely see through it.

That UV system hadn't actually been sterilizing anything for probably two or three years. The light was on, but virtually no UV energy was reaching the water.

The family had been drinking bacteria-laden well water for years without knowing it. They'd trusted a glowing blue light that meant nothing.

This is why UV maintenance matters. And this is why I want every well water owner in South Florida to understand exactly how these systems work, what can go wrong, and what it takes to keep them actually protecting your family.

How UV Sterilization Actually Works

Before we talk about maintenance, let's make sure you understand what's happening inside that stainless steel chamber.

The Basic Principle

UV sterilization uses ultraviolet light—specifically UV-C light at 254 nanometers wavelength—to kill microorganisms in water. When bacteria, viruses, or parasites pass through the UV chamber, the ultraviolet energy penetrates their cells and damages their DNA. This damage prevents them from reproducing, which effectively kills them.

It's the same principle as sunlight killing germs, just concentrated and optimized for water treatment.

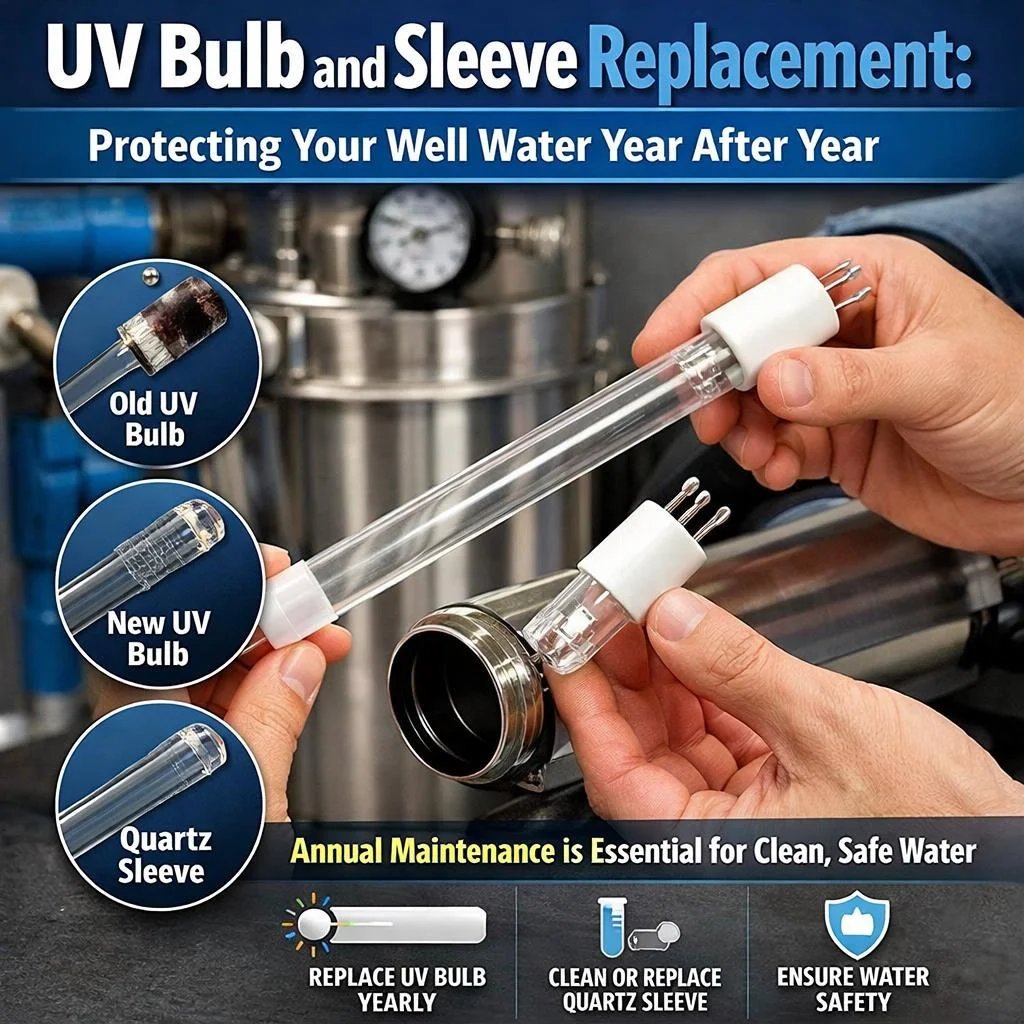

The Components

A typical residential UV system has four main parts:

The chamber is the stainless steel housing that water flows through. It's designed to ensure water passes close to the UV bulb with enough exposure time for effective sterilization.

The UV lamp (usually called a bulb) is a specialized fluorescent tube that produces UV-C light. It looks similar to a regular fluorescent tube but emits light in the germicidal UV spectrum rather than visible light.

The quartz sleeve is a clear tube that surrounds the UV lamp, separating it from the water. The sleeve lets UV light pass through while keeping the electrical lamp dry. Quartz is used because regular glass blocks UV light.

The ballast/controller is the electronic component that powers the lamp and often includes monitoring features—alerts for lamp failure, hour counters, and sometimes UV intensity sensors.

Why It's Critical for Well Water

Municipal water is treated with chlorine or chloramines that provide residual disinfection—the water stays protected as it travels through pipes to your home. Well water has no such protection. Whatever bacteria exist in the aquifer or enter through your well casing are in your water.

UV sterilization is the primary barrier between your family and waterborne illness when you're on well water. It's not optional equipment—it's essential protection.

That's why UV maintenance isn't something you can neglect and deal with later. When UV fails, you're drinking untreated well water.

The Problem With UV Bulbs: They Fade Before They Fail

Here's the thing that most people don't understand about UV lamps: they don't just burn out one day like a regular light bulb. They fade gradually over time, producing less and less UV energy until they're essentially useless—while still glowing.

The Visible Light Deception

A UV lamp produces some visible light (that blue glow you see through the viewport) in addition to the invisible UV-C light that actually kills bacteria. As the lamp ages, the UV-C output decreases much faster than the visible light output.

So you look at your UV system, see the blue light glowing, and assume everything's fine. Meanwhile, UV-C output might be at 40% of what's needed for effective sterilization. The light is on, but the protection is gone.

This is exactly what happened to that family in Loxahatchee. The bulb still glowed. The system still looked operational. But it hadn't truly sterilized their water in years.

The Numbers

A new UV lamp produces 100% of its rated UV-C output. Over the first year of continuous operation (8,760 hours), that output typically drops to 60-80% of original intensity, depending on lamp quality. By 12-14 months, most lamps are below the threshold needed for reliable disinfection.

Industry standard is to replace UV lamps annually—at 9,000 hours of operation or 12 months, whichever comes first. This isn't arbitrary. It's based on the decay curve of UV-C output and the minimum intensity needed to kill pathogens.

Some lamp manufacturers claim 2-year lifespans. In my experience, that's optimistic for South Florida conditions. Our warm water temperatures and water chemistry tend to accelerate lamp degradation. I recommend annual replacement regardless of manufacturer claims.

Why Waiting Until It Burns Out Is Dangerous

If you wait until the lamp actually stops working—visibly burns out—you've been drinking inadequately treated water for months. The lamp didn't fail the day it burned out. It failed gradually over the preceding weeks or months as UV output dropped below effective levels.

You also have no idea how long you've been unprotected. Maybe the lamp burned out yesterday. Maybe it's been providing inadequate disinfection for six months and finally gave up completely.

Annual replacement on a schedule means you always know your protection status. You replace the lamp before it degrades to dangerous levels, not after.

The Quartz Sleeve: The Part Everyone Forgets

If the UV lamp is the heart of your system, the quartz sleeve is the window that lets its energy reach the water. And it's the most neglected component in residential UV systems.

What the Sleeve Does

The quartz sleeve is a clear tube—think of it like a test tube—that surrounds the UV lamp. Water flows through the chamber around the outside of the sleeve, while the lamp stays dry inside.

Quartz is used because it's transparent to UV-C light. Regular glass would block the very wavelength that kills bacteria. The sleeve lets about 90% of UV energy pass through to the water.

The Fouling Problem

Here's what happens in real-world conditions: minerals in your water gradually deposit on the outside of the quartz sleeve. Calcium, magnesium, iron—all the stuff that's in South Florida well water—slowly coats the sleeve surface.

This mineral scale acts like a filter, blocking UV light from reaching the water. Even a thin film reduces UV transmission significantly. A heavily scaled sleeve might block 50-80% of UV energy—meaning your lamp could be working perfectly, but most of its output never reaches the water.

In South Florida, where well water is typically hard (high calcium and magnesium) and often contains iron, sleeve fouling is a major issue. I've pulled sleeves from systems in The Acreage and western Wellington that were so coated you couldn't see the lamp through them.

Cleaning vs. Replacement

Quartz sleeves can be cleaned—careful removal, soaking in a mild acid solution (usually citric acid or vinegar), gentle wiping, and reinstallation. This removes mineral scale and restores UV transmission.

However, sleeves also degrade over time. Repeated thermal cycling (heating and cooling), UV exposure, and handling gradually reduce their UV transparency even when clean. Micro-scratches from cleaning accumulate. The quartz itself can develop a slight haze.

My recommendation: clean sleeves annually when you replace the lamp, and replace the sleeve itself every 2-3 years. A new sleeve costs $40-80 depending on system size. That's cheap insurance compared to the cost of a contaminated water event.

Signs Your Sleeve Needs Attention

You can't always see sleeve fouling from outside the system—the viewport is small and the angle is limited. But there are clues:

If your UV intensity monitor (if equipped) shows declining output even after a lamp replacement, the sleeve is probably fouled. If you can see visible discoloration or haziness through the viewport, the sleeve definitely needs cleaning or replacement. If it's been more than a year since anyone looked at the sleeve, assume it needs attention.

The Complete UV Maintenance Schedule

Let me give you the maintenance schedule I recommend for every well water UV system in South Florida. This isn't manufacturer minimums—it's what actually keeps families safe given our local water conditions.

Annual Tasks (Every 12 Months)

Replace the UV lamp. No exceptions. Don't wait until it burns out. Don't trust manufacturer claims of longer life. Replace it annually on a set schedule—many people do it on the anniversary of installation, or at the start of each year so it's easy to remember.

Clean or replace the quartz sleeve. At minimum, remove the sleeve and inspect it. If there's visible fouling, clean it thoroughly. If it's been 2-3 years since replacement, install a new sleeve even if the old one looks okay.

Check and clean the UV chamber. While the lamp and sleeve are out, look inside the chamber for sediment accumulation or mineral deposits. Wipe down the interior if needed.

Verify electrical connections. Check that the ballast is functioning properly, all connections are secure, and any monitoring features are working. Replace ballast if it's showing signs of failure (flickering, buzzing, error codes).

Test the water. After completing UV maintenance, test your well water for coliform bacteria. This confirms your system is actually working. A clean test result gives you confidence for the year ahead.

Every 2-3 Years

Replace the quartz sleeve. Even if it looks clean, sleeve degradation affects UV transmission over time. Fresh quartz ensures maximum UV energy reaches your water.

Replace O-rings and seals. The O-rings that seal the quartz sleeve and chamber ends degrade over time. Hardened or cracked O-rings can leak, and leaks near electrical components are dangerous. Replace seals proactively during sleeve replacement.

Every 5-7 Years

Evaluate the entire system. UV technology improves over time. A system installed in 2018 may be significantly less efficient than current models. After 5-7 years, assess whether your system should be upgraded for better performance, lower energy consumption, or improved monitoring features.

Replace the ballast. Electronic ballasts typically last 7-10 years but can fail sooner. If your ballast is approaching this age, proactive replacement prevents unexpected failure.

What Happens During Professional UV Maintenance

When we come out for UV maintenance service, here's exactly what we do:

System Shutdown and Depressurization

First, we turn off power to the UV system and close the isolation valves (or bypass the system if equipped). Then we depressurize the chamber by opening the drain or a downstream faucet. Working on a pressurized system is dangerous and messy.

Lamp Removal

We disconnect the lamp from its electrical connector and carefully slide it out of the quartz sleeve. UV lamps are fragile—they're essentially long fluorescent tubes—and need to be handled gently.

We inspect the old lamp for any unusual discoloration or damage. A lamp that failed prematurely might indicate an electrical problem with the ballast.

Sleeve Removal and Inspection

The quartz sleeve slides out of the chamber once the lamp is removed. We inspect it carefully for fouling, scratches, cracks, or haziness.

If we're cleaning rather than replacing, we soak the sleeve in a descaling solution, then wipe it with a soft cloth. We never use abrasive materials—scratches scatter UV light and reduce effectiveness.

If we're replacing, the new sleeve gets installed with fresh O-rings.

Chamber Inspection and Cleaning

With the sleeve out, we can see inside the UV chamber. We look for sediment, mineral buildup, or any signs of corrosion. We wipe down the interior if needed.

We also check the inlet and outlet ports for any obstructions.

New Lamp Installation

The new lamp gets carefully inserted into the quartz sleeve, connected to the ballast, and tested for proper operation. We verify the lamp lights up and any monitoring features are working correctly.

System Restart and Testing

We close the drain, open the isolation valves, and slowly repressurize the system while checking for leaks around the sleeve seals. Once everything is confirmed watertight and operational, we test a water sample to verify bacteria-free output.

Documentation

We record what was done—lamp serial number, sleeve condition, any issues noted, test results. This documentation helps track system history and identify patterns if problems develop later.

DIY vs. Professional UV Maintenance

Can you replace your own UV lamp and sleeve? Technically, yes. It's not rocket science. But there are reasons many homeowners choose professional service.

The DIY Argument

UV lamps cost $80-150 depending on brand and wattage. Sleeves cost $40-80. O-rings are a few dollars. If you're comfortable with basic maintenance tasks, you can order parts online and do the replacement yourself in 30-45 minutes.

There are YouTube videos showing the process. It's straightforward: turn off power, close valves, remove old lamp, remove sleeve, clean or replace sleeve, insert new lamp, reassemble, restore power.

If you're handy, diligent about following instructions, and willing to handle the parts carefully, DIY is feasible.

The Professional Service Argument

That said, here's what professional service provides that DIY doesn't:

Proper disposal. UV lamps contain small amounts of mercury and shouldn't go in regular trash. We handle disposal properly.

Complete inspection. We don't just swap parts—we inspect the entire system, check electrical components, look for developing problems, and verify everything is working correctly.

Water testing. We test the output water to confirm the system is actually sterilizing effectively. You can't do this without testing equipment.

No risk of mistakes. A cracked quartz sleeve or damaged O-ring during DIY installation means your system leaks or doesn't seal properly. We've done thousands of these—we don't make those mistakes.

Documentation and reminders. We track when service was done and remind you when the next service is due. Most DIY maintainers forget after a year or two and end up with a neglected system.

Liability and peace of mind. If something goes wrong after professional service, we stand behind our work. If something goes wrong after DIY service, you own the problem.

Cost Comparison

DIY lamp and sleeve replacement might cost $120-200 in parts.

Professional UV maintenance service typically runs $175-275 including parts and labor.

You're paying $50-100 extra for professional service, inspection, testing, and peace of mind. For equipment that's literally the only thing protecting your family from waterborne illness, that premium is worth it to most people.

Warning Signs Your UV System Needs Immediate Attention

Don't wait for scheduled maintenance if you notice any of these:

The Lamp Is Out

If the blue glow is gone, your water is not being sterilized. Period. This is an emergency for well water users—don't drink the water until the lamp is replaced and the system is verified operational.

Alarm or Warning Light Is On

Most modern UV systems have audible or visual alarms that indicate lamp failure, low UV intensity, or other problems. Don't ignore these. An alarm means protection is compromised.

Visible Fouling Through the Viewport

If you look at the viewport and can't clearly see the lamp glowing—if there's visible scale, cloudiness, or discoloration—the sleeve needs cleaning or replacement immediately. UV output is being blocked.

Water Quality Changes

If your well water develops an unusual taste, odor, or appearance, something may have changed with your source water or your treatment system. Get the UV system inspected and the water tested.

It's Been More Than 12 Months Since Last Service

If you can't remember when the lamp was last replaced, or if you know it's been over a year, schedule service now. You may already be operating with inadequate UV output.

After Any System Disruption

If your UV system lost power for an extended period, if you had plumbing work done, or if anything disturbed the system, verify it's working properly before trusting it again.

Special Considerations for South Florida Well Water

Our local conditions create some specific challenges for UV systems that are worth understanding.

Iron and Manganese

Western Palm Beach County well water often contains elevated iron. Iron doesn't just stain your fixtures—it deposits on quartz sleeves faster than plain hard water minerals. If your well water has iron, expect to clean or replace your sleeve more frequently.

Some wells also have manganese, which creates dark brown/black deposits. Manganese fouling can be even harder to remove than iron fouling.

If your well has significant iron or manganese, you should have iron removal filtration before the UV system. This protects the UV sleeve and dramatically extends time between cleanings.

High Hardness

Most South Florida well water is hard—often 15-25 grains per gallon or more. This high mineral content accelerates sleeve fouling significantly. Annual sleeve cleaning is minimum; some high-hardness wells need cleaning every 6 months.

A water softener before the UV system reduces sleeve fouling dramatically. The softener removes calcium and magnesium before water reaches the UV chamber, keeping the sleeve cleaner longer.

Sediment

Some wells produce water with fine sand or sediment, especially after heavy rains or during drought conditions when water table levels change. Sediment can accumulate in the UV chamber and cloud the sleeve.

Sediment filtration (5-micron or finer) should always precede UV treatment. This protects the sleeve and ensures UV light can penetrate the water effectively.

Temperature

South Florida well water is relatively warm—often 75-80°F year-round. Warmer water can slightly accelerate lamp aging. This is another reason I recommend annual replacement rather than pushing for longer lamp life.

Power Fluctuations

Florida's summer thunderstorms cause frequent power fluctuations and outages. These electrical events stress UV ballasts and can shorten their lifespan. A surge protector on your UV system is cheap insurance against ballast damage.

The Real Cost of Neglecting UV Maintenance

Let me put this in perspective with real numbers.

Annual Maintenance Cost

Lamp: $80-150 Sleeve cleaning or replacement: $40-80 Professional service labor: $75-125 Water testing: $30-50

Total annual maintenance: $225-400

If you DIY, subtract the labor cost—call it $150-275 annually.

Cost of System Neglect

Let's say you skip maintenance for three years. Best case scenario: nothing bad happens, you got lucky, and you eventually do the maintenance you should have done all along.

Worst case scenario: your family gets sick from waterborne bacteria.

Medical bills for treating a bacterial infection: $500-5,000+ Lost work time while sick: $500-2,000 Potential hospitalization if infection is severe: $10,000+ Emergency UV service call after-hours: $200-400 Emergency water testing: $100-200 Temporary bottled water while system is repaired: $50-100

Total cost of one contamination event: $1,350-17,700+

The math is obvious. Annual maintenance is the cheapest option by far.

Equipment Damage From Neglect

A UV lamp left running years past its replacement date will eventually fail in a way that damages the ballast—power surges through a dying lamp stress electronic components. Ballast replacement adds $150-300 to your costs.

A sleeve left fouled for years can develop permanent etching from mineral deposits, requiring replacement rather than cleaning.

Seals left until they crack can cause leaks that damage surrounding equipment or create electrical hazards.

Neglect doesn't save money—it just delays and increases costs while leaving your family unprotected.

Setting Up a UV Maintenance Program

The easiest way to ensure UV maintenance actually happens is to remove yourself from the equation.

Annual Service Agreement

We offer maintenance agreements that include annual UV service automatically scheduled. We track when your system was last serviced, contact you when service is due, and handle everything—lamp, sleeve, inspection, testing.

You don't have to remember. You don't have to schedule. You don't have to think about it. It just happens.

For well water homeowners, this is the approach I recommend. UV maintenance is too important to leave to memory and good intentions.

Calendar Reminders

If you prefer to manage maintenance yourself, set recurring annual reminders. Many people use the New Year, their anniversary, or some other memorable date.

When the reminder pops up, schedule service immediately—don't push it off. Every week you delay is a week of degrading UV protection.

Hour Counters

Some UV systems have hour counters that track lamp runtime. When the counter hits 9,000 hours, it's time for replacement regardless of calendar date.

If your system has this feature, check it periodically. If it doesn't, assume 8,760 hours per year (24/7 operation) and replace annually.

Questions to Ask About Your UV System

If you have a UV system and aren't sure about its maintenance status, here are questions to investigate:

When was the lamp last replaced? If you don't know, it's probably overdue.

When was the sleeve last cleaned or replaced? If you don't know, it's probably fouled.

Is the lamp currently lit? Look at the viewport and confirm.

Are there any alarm indicators? Check for warning lights or error messages.

When was the water last tested for bacteria? If never, or if it's been more than a year, get it tested.

What brand and model is your system? This helps when ordering parts or scheduling service.

Is there sediment filtration before the UV? There should be.

Is there a water softener or iron filter before the UV? There should be if your water is hard or has iron.

If you can't answer these questions, schedule an inspection. A professional can assess your system's condition and get you on track with proper maintenance.

The Bottom Line

UV sterilization is the invisible shield between your family and waterborne illness. When it works, you never think about it—your water is safe, your family is healthy, everything is fine.

When it fails, you might not know until someone gets sick.

The difference between working and not working often comes down to maintenance. A $100 lamp. A $50 sleeve. An hour of service time once a year. That's all it takes to keep the protection active.

That family in Loxahatchee trusted a glowing blue light for six years. They didn't know the light meant nothing without the maintenance to back it up. They learned the hard way.

You don't have to learn that way. Replace your lamp annually. Clean or replace your sleeve. Test your water. Take the maintenance seriously.

Your well water is only as safe as your UV system's last service date.

Schedule Your UV Maintenance Service Today

Water Wizards offers complete UV system maintenance throughout Palm Beach, Broward, and Miami-Dade counties. Annual lamp and sleeve replacement, system inspection, water testing, and ongoing maintenance programs for well water homeowners.

Call 561-352-9989 or visit waterwizards.ai to schedule service.

Water Wizards Filtration — Florida's Water Filtration Experts

Serving Loxahatchee, The Acreage, Wellington, Royal Palm Beach, West Palm Beach, Jupiter, Palm Beach Gardens, and all South Florida communities relying on well water.

Frequently Asked Questions: UV Bulb and Sleeve Replacement

How often should I replace my UV lamp for well water sterilization?

Replace your UV lamp annually—every 12 months or 9,000 hours of operation, whichever comes first. This is industry standard and non-negotiable for well water safety. UV lamps don't burn out suddenly like regular bulbs; they gradually lose UV-C output while still producing visible light. A lamp that's been running 18+ months may still glow blue but produce only 40-50% of the UV energy needed to kill bacteria. In South Florida's warm conditions, lamp degradation can be even faster. Don't wait until the lamp burns out—by then, you've been drinking inadequately treated water for months. Schedule annual replacement on a consistent date you'll remember.

Why does my UV light still glow if it's not working properly?

UV lamps produce both visible light (the blue glow you see) and invisible UV-C light (the germicidal wavelength that kills bacteria). As lamps age, UV-C output decreases much faster than visible light output. A two-year-old lamp might produce a bright blue glow while delivering only 30-40% of its original UV-C energy. This is why the "it's still glowing" test is meaningless for determining UV effectiveness. The only ways to know if your UV system is actually sterilizing water are: replacing lamps on schedule (annual), using UV intensity monitors that measure actual UV-C output, and testing water for bacteria after treatment. Never trust the visible glow as proof of protection.

How do I know if my UV quartz sleeve needs cleaning or replacement?

Inspect your quartz sleeve during annual lamp replacement. Signs the sleeve needs immediate attention: visible mineral scale, cloudiness, or white/brown discoloration when viewed through the UV chamber viewport; declining UV intensity readings on your monitor even with a new lamp; sleeve has been in service 3+ years without replacement. In South Florida's hard, iron-rich well water, sleeves typically need cleaning annually and replacement every 2-3 years. If you can't clearly see the lamp through the sleeve when it's removed, UV transmission is compromised. Clean sleeves with citric acid solution or white vinegar, never abrasive materials that cause scratches. Replace the sleeve if cleaning doesn't restore clarity or if it's been 3+ years.

Can I replace my UV lamp myself or do I need professional service?

You can replace UV lamps yourself if you're comfortable with basic maintenance tasks. The process involves shutting off power, closing isolation valves, removing the old lamp, inspecting and cleaning the quartz sleeve, installing the new lamp, and restoring the system. It takes 30-45 minutes and lamps cost $80-150 depending on your system. However, professional service ($175-275 including parts) provides benefits DIY doesn't: proper lamp disposal (UV lamps contain mercury), complete system inspection, water quality testing to verify sterilization effectiveness, O-ring and seal inspection, and documentation for future reference. For equipment protecting your family from waterborne illness, most well water homeowners prefer professional service for the added assurance.

What happens if I don't replace my UV lamp on schedule?

Neglecting UV lamp replacement puts your family at risk for waterborne illness. As UV-C output decreases below effective sterilization levels, bacteria, viruses, and parasites in your well water pass through untreated. Common waterborne pathogens include E. coli, coliform bacteria, Giardia, and Cryptosporidium—all can cause serious gastrointestinal illness, especially in children, elderly, and immunocompromised individuals. Beyond health risks, neglect causes equipment damage: failing lamps stress ballasts, fouled sleeves develop permanent etching, and dried O-rings crack and leak. A contamination event resulting in family illness costs $1,500-15,000+ in medical bills, lost work, and emergency repairs—versus $200-400 for annual maintenance. The math strongly favors scheduled replacement.

How much does UV lamp and sleeve replacement cost in South Florida?

DIY UV maintenance costs $120-230 for parts: lamp ($80-150 depending on wattage and brand), quartz sleeve if replacing ($40-80), and O-rings ($5-15). Professional UV maintenance service runs $175-275 total including parts and labor. This typically includes lamp replacement, sleeve inspection and cleaning (replacement if needed), chamber inspection, O-ring check, system testing, and water quality verification. Annual maintenance contracts may offer slight discounts and include automatic scheduling. For reference, emergency UV service after a failure runs $250-400, and treating a family bacterial infection from contaminated water costs $500-5,000+. Annual maintenance is the most economical approach by far.

Do I need to replace the quartz sleeve every time I replace the UV lamp?

No—the quartz sleeve doesn't need replacement with every lamp change, but it does need inspection and usually cleaning. Annual lamp replacement should include removing the sleeve, inspecting for fouling and damage, and cleaning mineral deposits. Replace the sleeve every 2-3 years even if it appears clean, as UV transparency degrades gradually from exposure and handling. In South Florida well water with high hardness or iron content, sleeves may need cleaning every 6 months and replacement every 2 years. Signs requiring immediate sleeve replacement: visible scratches or etching, persistent cloudiness after cleaning, cracks, or if it's been 3+ years. A new sleeve costs $40-80—cheap insurance for a critical component.

My UV system has an alarm going off—what should I do?

A UV system alarm indicates compromised protection—take it seriously. Common alarm triggers: lamp failure (bulb burned out or UV-C output below threshold), power interruption, ballast malfunction, or low UV intensity from sleeve fouling. Immediately switch to bottled water for drinking and cooking until the system is repaired. Check the obvious first: is there power to the unit? Is the lamp visibly lit? Then call for service. Don't silence the alarm and continue using the water—the alarm exists because your water is not being adequately sterilized. For well water households, UV failure is an emergency. Same-day service should be available from reputable water treatment companies. Until repairs are complete, treat your well water as potentially contaminated.

Should I have my well water tested after UV maintenance?

Yes—water testing after UV maintenance confirms your system is actually working. Request coliform bacteria testing (the standard indicator for biological contamination) from a certified lab. Testing costs $30-75 and takes 24-48 hours for results. A negative result (no coliform detected) confirms your UV system is effectively sterilizing water. Professional UV maintenance service typically includes water testing; if doing DIY maintenance, arrange testing separately. Beyond post-maintenance testing, well water owners should test annually for bacteria as part of routine well monitoring. This catches problems between UV services and verifies ongoing protection. Don't assume your water is safe—confirm it with testing.